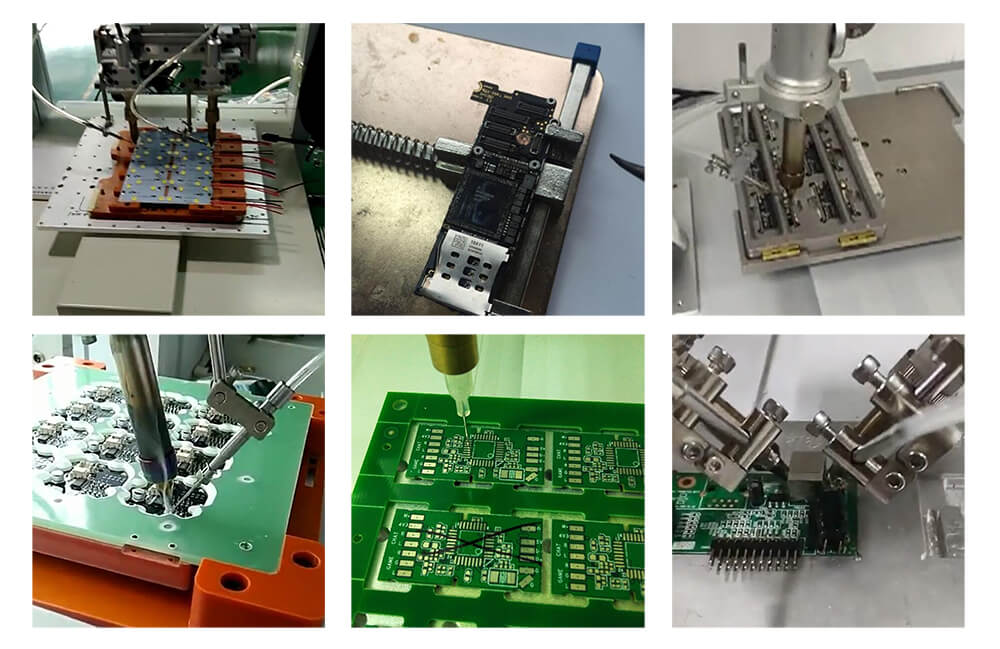

This machine is meticulously designed to meet the demanding needs of various industries, including automotive electronics, digital technology, electronic products, electro-acoustics, LCD manufacturing, and circuit board production. Its wide range of applications is a testament to its versatility and adaptability.

One of the distinguishing features of this soldering robot is its precise control over solder amount. By adjusting the feed time and feed speed, operators can ensure the optimal solder volume for every soldering job, resulting in high-quality, consistent soldering.

Furthermore, the robot incorporates a V-groove on the solder surface, a thoughtful design choice aimed at minimizing solder and flux splash during operation. This feature ensures a cleaner working environment and reduces potential defects or damage to the components being soldered, further enhancing the quality and reliability of the soldering process.

Parameters

- Flexible soldering method with spot welding, drag welding and other functions.

- The mechanical arm of the equipment is aluminum profile, no deformation, no rust, stable operation.

- The device writing work program can perform point-to-point, point-to-block copying and shorten the programming time.

- The device has an automatic cleaning function.

- Multi-axis linkage robots, all driven by precision stepping motors.

Specification

| ITEM | EM-331R |

| X/Y/Z Working Range | 300*300*100mm |

| R Axis | 360° |

| XYZ Speed | Max 300mm/s |

| Drive System | Stepping Motor + Timing Belt |

| Repeatability | ±0.02mm |

| Operation Method | Auto |

| Programming | Teach Pendant |

| Control | PLC |

| Document Support | CAD, CorelDRAW |

| Weight | 45kg |

| Dimension(L*W*H) | 516*585*800mm |

| Power Supply | 220V 50-60Hz 350W |

| ITEM | EM-5331S |

| X/Y/Z Working Range | 500*300*300*100mm |

| XYZ Speed | Max 300mm/s |

| Drive System | Stepping Motor + Timing Belt |

| Repeatability | ±0.02mm |

| Operation Method | Auto |

| Programming | Teach Pendant |

| Control | PLC |

| Document Support | CAD, CorelDRAW |

| Weight | 60kg |

| Dimension(L*W*H) | 716*585*800mm |

| Power Supply | 220V 50-60Hz 350W |