Key Advantages of the Vision-Guided Conveyor Dispensing System

- Free Placement, Zero Hassle

Products can be randomly placed on the conveyor belt – no precise positioning or fixtures required. - Auto-Detection & Precision Dispensing

The advanced vision system instantly recognizes product positions and orientations, ensuring 100% accurate glue application every time. - Adapt to Any Shape, Boost Productivity

Seamlessly handles irregular or varying product designs, doubling throughput while eliminating manual adjustments.

Working Process

- Place Product on Conveyor Belt: Products are placed onto the conveyor belt for processing.

- Product Enters Camera Range: As the conveyor belt moves, the product enters the field of view of the camera.

- Camera Identifies Product Features: The camera captures and identifies the product’s shape or other specific features. The industrial computer then generates the dispensing parameters based on this data.

- Conveyor Belt Speed Monitoring: An electronic encoder on the conveyor belt continuously monitors and reports the belt’s speed.

- Product Enters Glue Application Area: The product moves into the designated area where glue will be applied.

- System Matches Features and Speed for Glue Application: The system matches the identified product features with the conveyor belt speed to guide the glue dispensing mechanism for synchronized application.

- Product Exits Conveyor Belt: After the glue application, the product continues on the conveyor belt and exits the system.

Parameters

| Parameter | Specification |

|---|---|

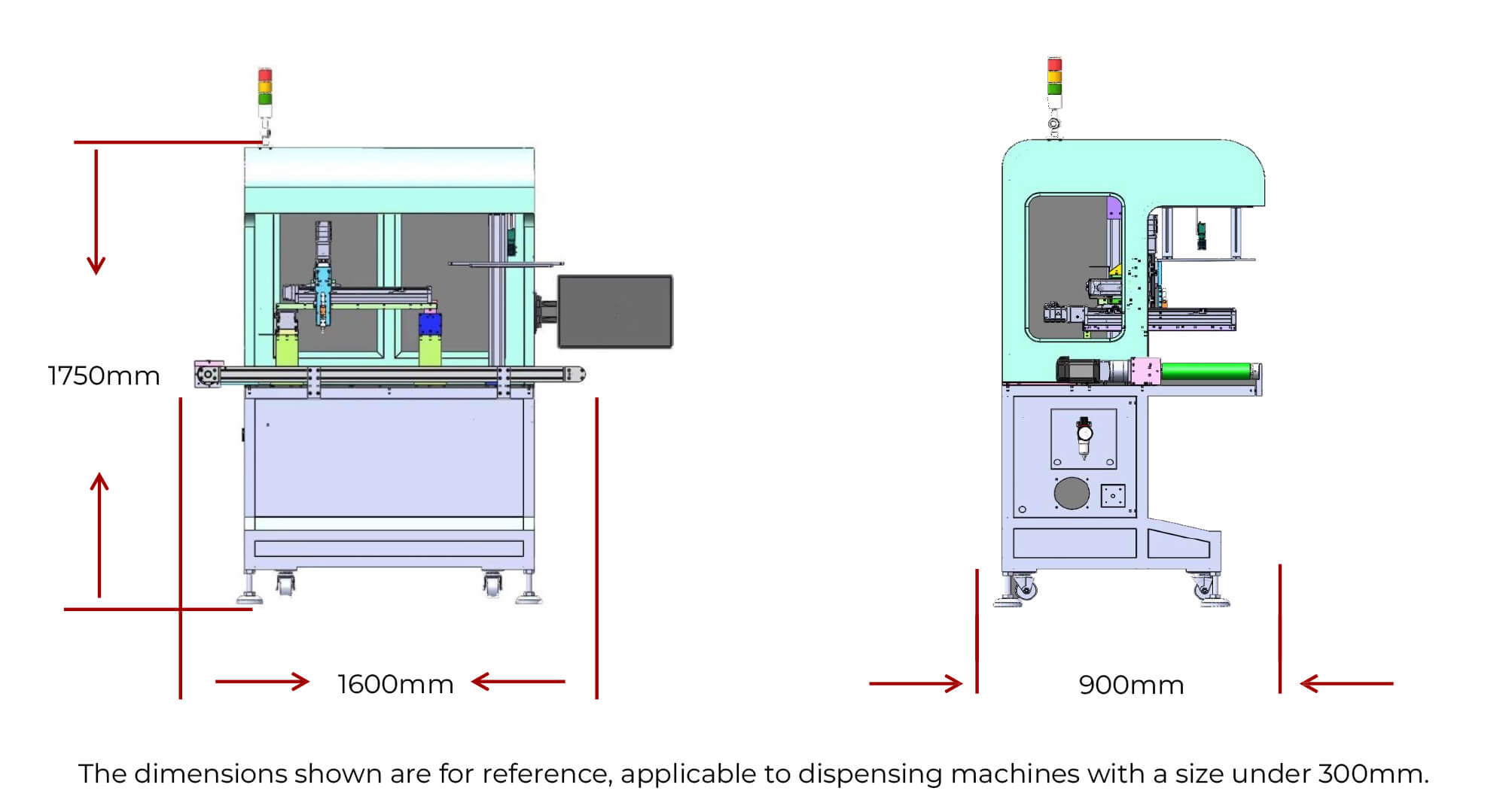

| Equipment Travel | X: 300mm; Y: 300mm; Z: 100mm |

| Dispensing Speed | XY: 800mm/s; Z: 500mm/s |

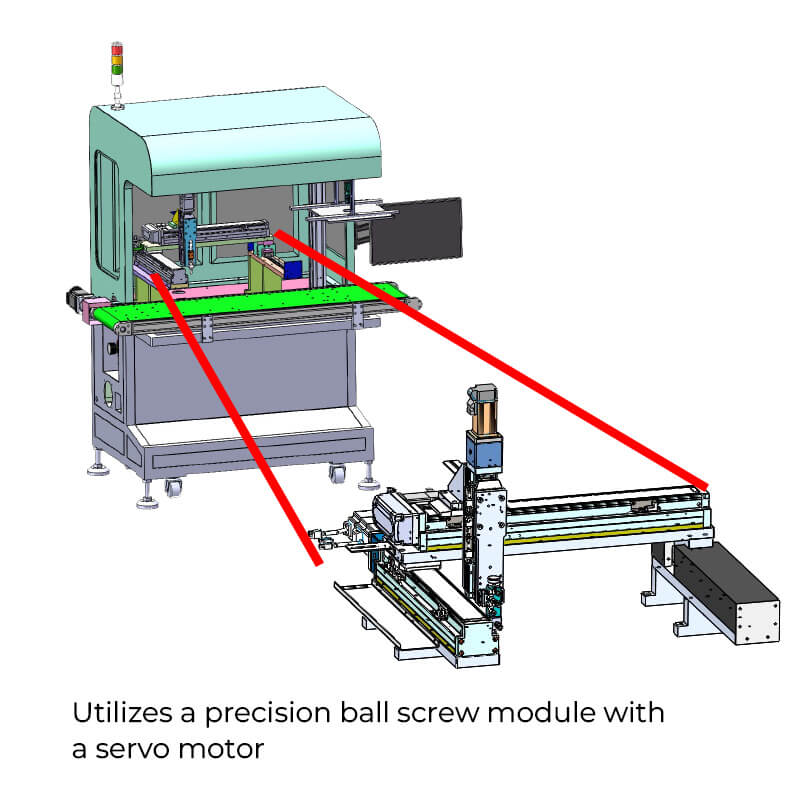

| Transmission Method | XYZ: Lead Screw + Servo Motor |

| Equipment Dimensions | 1600*900*1750mm |

| Field of View | 300*300mm |

| Adhesive Supply System | Standard |

| Operating Voltage | AC-220V |

| Operating Air Pressure | 0.6-1.2Mpa |

| Equipment Power | 2000W |