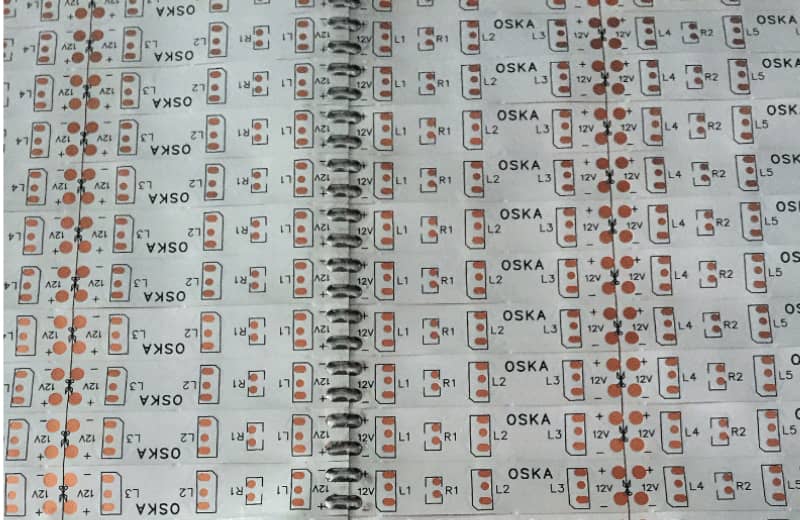

The Double Platform LED Light Strip Soldering Machine – with Cleaning Function revolutionizes the LED strip manufacturing process with its advanced technology and integrated cleaning function. This specialized equipment excels in executing standard 5-meter LED strip plate connection operations, and its capability to automatically clean soldering pads is a significant breakthrough, eliminating manual labor and enhancing productivity.

Our soldering machine is engineered with a user-focused design in mind, offering simple programming and effortless operation. Even new staff members can achieve expert-level welding results, ensuring consistency in quality and reducing the need for extensive training.

Performance is a hallmark of this machine. Equipped with a double head, it speeds up the welding process dramatically, matching the output of 3-4 workers. This increased efficiency doesn’t compromise the quality of work, delivering excellent solder joint consistency and significantly reducing tin wire consumption.

The machine’s robust high-power heating controller ensures stability during continuous welding operations, a critical aspect in maintaining optimal performance and product quality. Its multi-axis manipulator employs an advanced motion control algorithm to enhance kinematic positioning accuracy and repeatability precision, reflecting the machine’s commitment to precision and reliability.

The machine’s design caters to the professional needs of lamp batten production. Its user-friendly structure facilitates manual feeding and feeding, ensuring smooth operation during manufacturing. Demonstrating impressive production efficiency, it can handle 1500-2400 meters per hour, a testament to its superior performance and productivity-enhancing capabilities.

Application of LED Light Strip Soldering Machine:

- Simple programming, Easy operation, new staff can achieve the welding effect of skilled workers.

- Welding speed, high efficiency with double head, a solder machine can save 3-4 people.

- Save tin wire, good consistency of solder joint.

- High power heating controller ensures the stability of continuous welding.

- Multi-axis manipulator, advanced motion control algorithm, to improve the kinematic positioning accuracy and repeatability accuracy.

- According to the professional design of the lamp batten, it is convenient for manual feeding and feeding.

- Production efficiency: 1500-2400 metres /H.