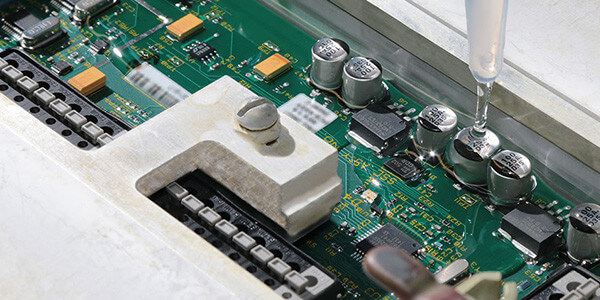

Senyawa pot adalah resin polimer termoseting yang digunakan dalam manufaktur elektronik untuk merangkum dan melindungi komponen sensitif dari bahaya lingkungan seperti kelembaban, debu, bahan kimia, dan guncangan mekanis. Senyawa -senyawa ini, umumnya terbuat dari epoksi, uretan, atau silikon, membentuk cangkang yang keras dan pelindung yang meningkatkan keandalan perangkat, terutama di lingkungan yang keras seperti aplikasi otomotif, kedirgantaraan, dan medis. Namun, ada beberapa contoh di mana penghapusan menjadi perlu, seperti untuk perbaikan, peningkatan, daur ulang, atau rekayasa terbalik. Menghapus senyawa pot dapat menantang karena sifatnya yang tahan lama dan risiko merusak elektronik yang mendasarinya, membutuhkan pemilihan metode dan kepatuhan terhadap protokol keselamatan yang cermat.

Tujuan dan tantangan penghapusan

Alasan utama untuk menghilangkan senyawa pot meliputi:

- Memperbaiki: Mengakses komponen yang salah untuk pemecahan masalah atau penggantian.

- Meningkatkan: Memodifikasi atau meningkatkan rakitan elektronik.

- Daur ulang: Menyelamatkan komponen yang dapat digunakan dari perangkat usang.

- REVERSE REGING: Mempelajari desain internal untuk analisis atau inovasi.

Tantangan muncul dari adhesi yang kuat dan resistensi kimia, yang dapat membuat penghapusan sulit tanpa merusak elektronik. Metode yang agresif dapat menyebabkan kerusakan komponen, kerusakan listrik, pelepasan bahan berbahaya, kontaminasi, cedera fisik, atau jaminan batal. Oleh karena itu, pendekatan sistematis sangat penting, mengingat jenis bahan pot dan sensitivitas komponen yang terlibat.

Metode untuk menghilangkan senyawa pot elektronik

Di bawah ini adalah rincian rinci metode untuk menghilangkan senyawa pot, termasuk alat, tindakan pencegahan keselamatan, dan pertimbangan spesifik. Metode -metode ini dipesan dari yang umumnya lebih aman hingga lebih khusus, berdasarkan wawasan profesional dan komunitas.

1. Senjata panas

Keterangan: Senjata panas menerapkan panas yang terkontrol untuk melunakkan senyawa pot melalui ekspansi termal, membuatnya lebih mudah untuk dipisahkan dari substrat. Metode ini efektif untuk senyawa yang menjadi lentur pada suhu tinggi, seperti beberapa epoksi dan uretan.

Alat/Bahan: Senjata panas, termokopel untuk pemantauan suhu, termometer inframerah untuk pemeriksaan suhu permukaan.

Tindakan pencegahan keselamatan:

- Suhu kontrol untuk mencegah kerusakan elektronik; Kisaran khas sekitar 150 ° C, tetapi monitor dengan cermat.

- Bekerja di daerah yang berventilasi baik untuk menghindari menghirup asap.

- Kenakan sarung tangan tahan panas dan kacamata pengaman untuk melindungi dari luka bakar dan percikan.

Pertimbangan khusus:

- Panaskan secara bertahap dan melokalisasi pemanasan untuk menghindari guncangan termal, yang dapat memecahkan komponen.

- Suhu monitor untuk memastikan tidak melebihi batas aman untuk elektronik (mis., Hindari melebihi 200 ° C untuk sebagian besar PCB).

- Wawasan masyarakat menunjukkan merendam air di antara sesi pemanasan dapat membantu pemisahan untuk beberapa senyawa.

2. Pelarut Kimia

Keterangan: Pelarut kimia melarutkan atau melemahkan ikatan senyawa pot, memungkinkan untuk lebih mudah dihapus. Pelarut umum termasuk aseton, MEK (metil etil keton), isopropil alkohol, dan agen dekapsulasi khusus. Efektivitas tergantung pada jenis senyawa, dengan epoksi sering membutuhkan pelarut yang lebih kuat.

Alat/Bahan: Pelarut (mis., Aseton, MEK), kuas untuk aplikasi, kain untuk menyeka, wadah untuk dibuang.

Tindakan pencegahan keselamatan:

- Gunakan di area berventilasi yang baik atau tudung asap untuk menghindari menghirup uap beracun.

- Kenakan APD, termasuk sarung tangan nitril, kacamata pengaman, dan masker respirator P100.

- Tinjau lembar data keselamatan material (MSD) untuk setiap pelarut untuk memahami bahaya dan penanganan.

- Pastikan pembuangan limbah yang tepat, mengikuti peraturan lokal.

Pertimbangan khusus:

- Identifikasi jenis senyawa pot (mis., Epoksi, uretan) untuk memilih pelarut yang sesuai; Misalnya, MEK efektif untuk epoksi tetapi dapat merusak plastik.

- Pantau kemajuan pembubaran, karena beberapa pelarut mungkin membutuhkan waktu berjam -jam untuk melunakkan senyawa.

- Bersihkan pelarut residu secara menyeluruh untuk mencegah korosi atau residu yang mempengaruhi komponen.

- Forum komunitas mencatat bahwa pelarut seperti aseton dapat melarutkan epoksi PCB, meninggalkan anyaman fiberglass, jadi uji pada area kecil terlebih dahulu.

3. Alat Mekanik

Keterangan: Setelah melunakkan dengan panas atau pelarut, alat mekanis digunakan untuk memecah secara fisik dan menghilangkan bahan pot. Metode ini padat karya tetapi efektif untuk pemindahan lokal.

Alat/Bahan: Pahat, pencakar, obeng, pilihan gigi untuk pekerjaan presisi.

Tindakan pencegahan keselamatan:

- Gunakan alat yang sesuai untuk menghindari komponen yang merusak; Pilih alat non-logam untuk area halus.

- Kenakan perlengkapan pelindung, termasuk sarung tangan dan kacamata pengaman, untuk melindungi dari tepi yang tajam dan puing -puing.

Pertimbangan khusus:

- Berhati -hatilah untuk mencegah kerusakan pada komponen yang mendasarinya, terutama sambungan dan jejak solder.

- Metode ini dapat menghasilkan puing -puing, membutuhkan pembersihan untuk menghindari kontaminasi.

- Saran komunitas termasuk menggunakan alat Dremel untuk memotong, tetapi dengan hati -hati untuk menghindari komponen overheating atau goresan.

4. Pembersih Ultrasonik

Keterangan: Pembersih ultrasonik menggunakan gelombang suara frekuensi tinggi (biasanya 40 kHz) untuk mengaduk pelarut, secara efektif menghilangkan senyawa pot dari komponen kecil atau rumit. Metode ini tidak merusak dan cocok untuk elektronik halus.

Alat/Bahan: Pembersih ultrasonik, pelarut yang kompatibel (mis., Aseton, isopropil alkohol).

Tindakan pencegahan keselamatan:

- Pastikan ventilasi yang tepat untuk mengelola uap pelarut.

- Kenakan APD, termasuk sarung tangan dan kacamata.

- Buang pelarut limbah dengan benar, mengikuti peraturan lingkungan.

Pertimbangan khusus:

- Mengoptimalkan frekuensi, suhu (mis., 50-60 ° C), dan durasi untuk hasil terbaik; Siklus khas adalah 10-30 menit.

- Cocok untuk penghapusan non-destruktif, terutama untuk komponen dengan toleransi yang ketat.

- Wawasan komunitas menyarankan metode ini efektif untuk bagian -bagian kecil tetapi mungkin memerlukan beberapa siklus untuk lapisan pot tebal.

5. Bahan abrasif

Keterangan: Setelah melunakkan senyawa pot, bahan abrasif seperti amplas (mis., 80-120 grit) atau roda abrasif digunakan untuk menggosok bahan. Metode ini efektif untuk penghapusan tingkat permukaan tetapi menghasilkan puing-puing yang signifikan.

Alat/Bahan: Amplas, roda abrasif, mungkin alat putar untuk area yang lebih besar.

Tindakan pencegahan keselamatan:

- Kenakan kacamata pengaman, sarung tangan, dan respirator untuk melindungi dari debu dan puing -puing.

- Bekerja di daerah yang berventilasi baik untuk mengelola partikel di udara.

Pertimbangan khusus:

- Membutuhkan pelunakan sebelumnya dengan panas atau pelarut untuk menghindari kekuatan yang berlebihan.

- Menghasilkan panas dan puing -puing, sehingga ventilasi sangat penting untuk mencegah penghirupan dan kontaminasi komponen.

- Forum Komunitas Catatan metode ini dapat menggaruk komponen jika tidak dikendalikan, jadi gunakan amplas halus untuk finishing.

6. Teknik pembekuan

Keterangan: Teknik pembekuan, seperti menggunakan nitrogen cair (-196 ° C/-321 ° F) atau campuran isopropil alkohol (IPA) dan es kering (~ -110 ° C), buat senyawa pot rapuh, memungkinkan chipping atau peeling yang lebih mudah. Metode ini efektif untuk senyawa tertentu tetapi berisiko tegangan termal.

Alat/Bahan: Nitrogen cair, es kering dengan IPA, alat non-logam seperti pencakar plastik.

Tindakan pencegahan keselamatan:

- Kontrol pendinginan untuk menghindari tegangan termal pada komponen, yang dapat memecahkan sambungan solder atau delaminasi PCB.

- Kenakan sarung tangan berat dan pakaian pelindung untuk mencegah radang dingin dari dingin yang ekstrem.

Pertimbangan khusus:

- Mungkin tidak berfungsi untuk semua senyawa, terutama yang fleksibel seperti silikon.

- Risiko merusak komponen sensitif karena perubahan suhu yang cepat.

- Wawasan komunitas menyarankan metode ini efektif untuk epoksi tetapi membutuhkan kehati -hatian, karena dingin yang ekstrem dapat membekukan kulit atau jari.

7. Pelarut ramah lingkungan

Keterangan: Pelarut yang dapat terbiodegradasi seperti berbasis jeruk (mis., D-Limonene), produk berbasis kedelai, atau terpene menawarkan alternatif yang sadar lingkungan untuk menghilangkan senyawa pot. Ini kurang beracun tetapi mungkin memerlukan bantuan mekanis untuk penghapusan total.

Alat/Bahan: Pelarut ramah lingkungan, kuas, kain.

Tindakan pencegahan keselamatan:

- Pastikan ventilasi, karena pelarut ramah lingkungan dapat memancarkan uap.

- Kenakan APD, termasuk sarung tangan dan kacamata, dan kompatibilitas uji dengan senyawa pot.

- Buang limbah dengan benar, mengikuti pedoman lingkungan.

Pertimbangan khusus:

- Efektivitas dapat bervariasi; mungkin perlu digabungkan dengan metode mekanis seperti mengikis.

- Cocok untuk aplikasi di mana meminimalkan dampak lingkungan adalah prioritas.

Metode tambahan dari wawasan komunitas

Sementara sumber profesional menyediakan metode terstruktur, forum dan diskusi komunitas menawarkan tips praktis dan pendekatan alternatif, seringkali dengan risiko yang lebih tinggi:

- Pemanasan hingga 150 ° C.: Beberapa senyawa terpisah ketika dipanaskan hingga suhu ini; Rendam dalam air antar sesi dapat membantu pemisahan. (Risiko: merusak elektronik akibat overheating)

- Tempa: Oleskan pukulan berat untuk memisahkan lapisan, efektif jika di satu sisi PCB. (Risiko: Risiko tinggi merusak elektronik, tidak direkomendasikan untuk komponen halus)

- Mandi aseton: Rendam selama sekitar 1 jam, kikis material yang lunak, dan ulangi sesuai kebutuhan. (Risiko: Dapat melarutkan epoksi PCB, meninggalkan anyaman fiberglass; membutuhkan sarung tangan dan kacamata)

- Mandi asam nitrat yang dipanaskan: Gunakan ~ 70% asam nitrat, membutuhkan pengaturan laboratorium yang tepat dengan pelepasan asap. (Risiko tinggi; tidak direkomendasikan tanpa keahlian, karena dapat merusak komponen dan berbahaya)

- Celah dingin dengan IPA dan es kering: Campurkan IPA dengan es kering yang dihancurkan (~ -110 ° C) untuk memotong senyawa, menggunakan sarung tangan berat. (Risiko: Dingin ekstrem dapat membekukan kulit; potensi kerusakan termal pada elektronik)

- Agen dekapsulasi khusus: Senyawa spesifik ada untuk dekapsulasi, tetapi mereka digambarkan sebagai jahat dan mahal, membutuhkan kondisi laboratorium. (Risiko tinggi; tidak praktis untuk DIY)

Metode komunitas ini harus didekati dengan hati -hati dan hanya dicoba jika benar -benar diperlukan, mengingat potensi kerusakan dan bahaya keselamatan.

Tindakan pencegahan dan risiko keselamatan

Keamanan adalah yang terpenting saat menghilangkan senyawa pot, mengingat potensi paparan kimia, kerusakan termal, dan cedera fisik:

Tindakan pencegahan umum:

- Selalu pakai Peralatan Pelindung Pribadi (APD): Kacamata pengaman, sarung tangan nitril, topeng respirator P100, dan pakaian pelindung.

- Bekerja di area yang berventilasi baik atau menggunakan sistem ekstraksi asap, terutama dengan pelarut atau pemanasan.

- Tinjau MSDS untuk bahan kimia apa pun yang digunakan untuk memahami bahaya, penanganan, dan persyaratan pembuangan.

- Memiliki prosedur tanggap darurat, termasuk pertolongan pertama untuk paparan kimia, luka bakar, atau radang dingin.

Risiko metode agresif:

- Kerusakan Komponen: Metode mekanis seperti palu atau penghapusan abrasif dapat menggaruk atau mematahkan komponen.

- Malfungsi Listrik: Pelarut atau panas dapat mengikat jejak atau larut solder.

- Pelepasan Bahan Berbahaya: Beberapa senyawa dapat melepaskan asap beracun saat dipanaskan atau dilarutkan.

- Kontaminasi: Puing -puing dari pemindahan mekanis dapat mencemari elektronik sensitif.

- Cedera fisik: Alat tajam atau suhu ekstrem (mis., Nitrogen cair) menimbulkan risiko pemotongan atau radang dingin.

- VOIDING GARANSI: Penghapusan tidak sah dapat membatalkan jaminan pabrikan.

Kapan harus mencari bantuan profesional

Untuk pemindahan yang kompleks atau kritis-terutama ketika berhadapan dengan bahan berbahaya, komponen bernilai tinggi, atau rakitan yang rumit-disarankan untuk mencari layanan profesional. Perusahaan dan teknisi khusus memiliki keahlian dan peralatan untuk menangani tugas -tugas tersebut dengan aman dan efektif. Contohnya termasuk:

- Teknisi perbaikan elektronik dengan pengalaman dalam de-potting.

- Perusahaan teknik yang berspesialisasi dalam ilmu material.

- Perusahaan lingkungan atau daur ulang untuk pembuangan yang aman.

- Produsen peralatan yang menawarkan dukungan untuk produk mereka.

- Lembaga penelitian dengan fasilitas laboratorium untuk penghapusan lanjutan.

Studi Kasus dan Contoh

Sementara studi kasus spesifik tidak dirinci dalam sumber, contoh -contoh praktis dari forum komunitas menggambarkan skenario umum:

- Seorang pengguna di Reddit (2023) berhasil menghilangkan epoksi hitam menggunakan aseton dan panas, memotongnya secara bertahap, tetapi mencatat kerusakan minimal pada komponen.

- Posting forum lain (Excineering Stack Exchange, 2016) membahas menghilangkan pot dari PCB untuk diperbaiki, menggunakan alat panas dan mekanik, tetapi menyoroti risiko kerusakan sambungan solder.

- Halaman Proyek Pribadi (Kevtris.org) Rinci Membatalkan Pemotongan Sistem Pidato Pribadi Votrax, menggunakan metode panas dan mekanis, menekankan kesulitan penghapusan epoksi.

Contoh -contoh ini menggarisbawahi pentingnya kesabaran dan keselamatan, terutama bagi penggemar DIY.

Kesimpulan

Menghapus senyawa pot elektronik membutuhkan pertimbangan yang cermat dari metode ini berdasarkan jenis senyawa (mis. Epoksi, silikon) dan sensitivitas komponen yang terlibat. Meskipun ada beberapa teknik yang tersedia - dari senjata panas dan pelarut hingga alat mekanis dan pembersih ultrasonik - masing -masing hadir dengan serangkaian tindakan pencegahan dan risiko keselamatan sendiri. Selalu memprioritaskan keselamatan, memakai APD yang sesuai, dan bekerja di daerah berventilasi. Untuk pemindahan yang menantang, pertimbangkan bantuan profesional untuk meminimalkan kerusakan dan memastikan kepatuhan dengan standar keselamatan. Dengan mengikuti pedoman yang diuraikan dalam artikel ini, Anda dapat berhasil menghilangkan senyawa pot sambil menjaga integritas elektronik Anda.