In electronic enclosures, potting boxes is a prominent solution, safeguarding internal components from both physical harm and environmental interferences while enhancing electronic insulation.

The unique aspect of these enclosures lies in their distinct fillers – semi-solid compounds adept at preserving and shielding the components housed within. This innovative technique diverges from traditional enclosure design methods, and understandably, can cause confusion.

In the following sections, we unravel the rudiments of electronic potting, provide an in-depth analysis of the top three potting compounds prevalent in the industry, and offer strategic advice to guide you in selecting the optimal potting material and successfully potting your electronics.

What is Glue Potting?

Glue potting refers to the process of encapsulating an electronic assembly into a pot or case with a compound to protect and secure its components. The glue or potting compound used in this process can be epoxy, silicone, urethane, or other polymers that cure to form a tough, durable layer around the electronics.

The primary purpose of glue potting is to protect electronic components from environmental factors such as moisture, dust, temperature fluctuations, and vibrations. The potting compound acts as a barrier, insulating the components from these potentially damaging factors.

Additionally, glue potting can improve the assembly’s mechanical stability, reduce the risk of damage from shock or vibration, and enhance the heat dissipation characteristics of certain components. Furthermore, it can prevent tampering or reverse engineering of proprietary hardware by making the components difficult to access without damaging them.

Which is the Best Compound for Electronics Potting?

Epoxies, polyurethanes, and silicones are the three primary potting compounds used in electronics, each offering its unique advantages and considerations.

Epoxies Potting Compounds

Epoxies are a type of thermoset polymer that forms an extremely strong bond and offers excellent resistance to heat, chemicals, and electricity. This makes them an excellent choice for high-stress, high-temperature, and high-voltage applications. However, epoxies are typically rigid and can be brittle, which can make them less ideal for applications that require flexibility or involve thermal cycling.

Polyurethanes Potting Compounds

Polyurethanes are flexible and resistant to wear, making them ideal for applications that involve movement or vibration. They also have excellent electrical properties and good resistance to water and various chemicals. However, they may not be as suitable for high-temperature environments as epoxies and can degrade over time with prolonged exposure to UV light.

Silicones Potting Compounds

Silicones are known for their flexibility and excellent temperature resistance, making them an excellent choice for applications that involve thermal cycling or high temperatures. They are also resistant to UV light and can be used in outdoor applications. However, they may not have as good chemical or abrasion resistance as the other two types and may not form as strong a bond.

Here’s a comparison table summarizing the characteristics of each material:

| Material | Pros | Cons | Suitable Applications |

|---|---|---|---|

| Epoxy | Excellent heat, chemical, and electrical resistance; strong bond | Rigid, potentially brittle; not ideal for thermal cycling | High-stress, high-temperature, and high-voltage applications |

| Polyurethane | Flexible, wear-resistant; good electrical properties and water/chemical resistance | Not suitable for high temperatures; can degrade under UV light | Applications involving movement or vibration |

| Silicone | Flexible; excellent temperature and UV resistance | Lower chemical and abrasion resistance; weaker bond | Applications involving thermal cycling or high temperatures, outdoor applications |

The Electronic Potting Process

1. Preparation of the Substrate: This first step involves prepping the electronic component or assembly that will be potted. The component should be clean, dry, and free of any contaminants. This step may also involve setting up the shell or casing that will contain the potting compound, ensuring it is appropriately sized and properly sealed to prevent leakage.

2. Mixing the Adhesive: Potting compounds usually come in two parts that must be mixed together before use. The two components (usually known as the resin and the hardener) are mixed together in the correct ratio specified by the manufacturer. It is critical to thoroughly mix the two parts to ensure a complete reaction and cure.

3. Dispensing the Adhesive: After mixing, the potting compound is dispensed into the enclosure containing the electronic component or assembly. This is usually done manually or with the aid of a dispensing machine that can control the flow rate and the volume of the compound dispensed. The potting compound should fill the entire enclosure and encapsulate all parts of the component.

4. Curing the Adhesive: After dispensing, the potting compound needs to cure or harden. The curing process can vary depending on the type of potting compound used. Some compounds cure at room temperature, while others require heat. It’s important to allow the potting compound to fully cure before handling or testing the potted component.

Specific steps can vary depending on the exact type of potting compound used and the specifications of the component being potted. Any dispensing problems, feel free to ask us.

Choosing the Appropriate Potting Compound for Your Project

The optimal potting compound for your project hinges on several key factors. Here, we outline the four essential aspects to consider:

- Hardness: The hardness of a compound is directly linked to its weather and abrasion resistance and its capacity for Ingress Protection (IP). If your project calls for a harder, more rigid compound, epoxies and urethanes are worthy choices, offering hardness up to 80D. For applications requiring flexibility without compromising hardness, silicon compounds, with a hardness ranging from 10A to 60A, may be an ideal fit.

- Viscosity: The flowability and self-leveling characteristics of low-viscosity compounds make them suitable for most potting applications. Standard potting compounds typically adhere to this design. However, if your project demands a thicker compound, higher viscosity variants are available.

- Color: The color of your potting compound could be a vital factor if the aesthetic and visibility of the finished product are important. In most instances, a dark, opaque color will suffice. However, if you’re working with LEDs, transparent compounds are necessary to ensure visibility.

- Thermal Conductivity: Potting compounds with higher thermal conductivity facilitate more efficient management and dissipation of heat generated by your electronic devices. While silicone, epoxy, and urethane all perform well in this aspect, silicone outperforms the others.

When weighing these factors, remember to consider the specific needs of your application and the characteristics of epoxies, polyurethanes, and silicones, as detailed earlier in this article.

Considerations for Potting an Electronic Assembly

While the potting process may vary between manufacturers, the following guidelines can help maintain optimal product quality:

- Preheat the Resin: Warming the resin prior to potting enhances the flow of the compound during application. Consult your supplier to ascertain the ideal temperature for optimal flow for your chosen compound.

- Maintain the Right Resin-to-Hardener Ratio: Balancing weight ratios between resin and hardener is vital to create a potting compound that strikes the right balance between hardness and flexibility. It may require several trials to achieve the ideal ratio.

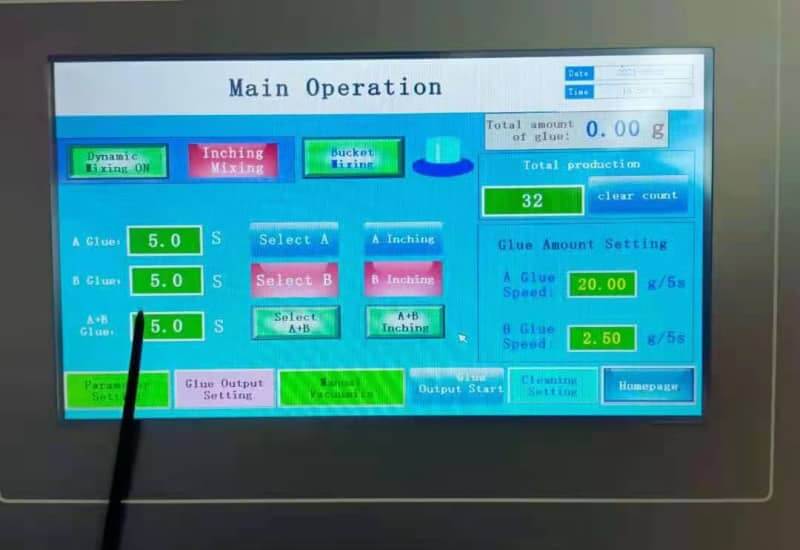

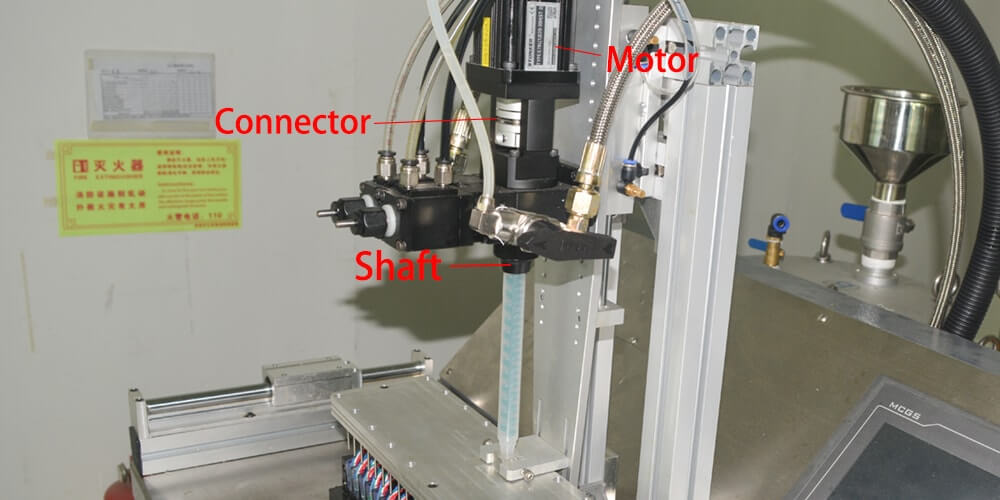

- Utilize a Detachable Mixing Nozzle for Homogenous Mixing: Once you have established the ideal resin-hardener ratio, use a dynamic mixing nozzle to ensure a thoroughly mixed, homogeneous potting compound. Dynamic mixing nozzles work by forcing the two components into a chamber, where they are then stirred together using a motor-driven mixer. This results in a consistent, bubble-free mixture, eliminating manual stirring errors and ensuring a precise, high-quality mix.

- Dispense Weight/Speed Control: The desired dispense volume or weight can be achieved either through multiple smaller shots or one larger shot, depending on your preference. Using an adjustable cylinder piston is recommended to effectively regulate the dispense amount.

Introducing Our Advanced Glue Dispensing Equipment

Navigating the intricate process of electronic potting requires a reliable and efficient tool. Our state-of-the-art glue dispensing equipment is meticulously designed to streamline this process, ensuring that each step is performed with precision and consistency.

Preheating Function: Our dispenser features a built-in preheating function, allowing for optimal compound flow during application. This ensures that your chosen potting compound is heated to its ideal temperature before application, promoting an even distribution and eliminating potential flow issues.

Adjustable Resin-to-Hardener Ratio: The glue dispensing equipment we offer allows for adjustable resin-to-hardener ratios, giving you the flexibility to alter these proportions based on your specific requirements. This function ensures that you consistently achieve the perfect balance between hardness and flexibility in your potting compound.

Dynamic Mixing Function: At the heart of our glue dispenser lies the dynamic mixing function. This feature facilitates the thorough mixing of resin and hardener using a motor-driven mixer within the dispensing nozzle. The result is a homogeneous, bubble-free mixture, reducing errors commonly associated with manual mixing. Additionally, the dynamic mixer operates under pressure, ensuring an even blend every time.

Glue Tank Vacuum Function: Another key feature of our dispensing equipment is the glue tank vacuum function. This crucial function creates a vacuum within the glue tank, which helps to eliminate any entrapped air in the adhesive before it is dispensed. This results in a bubble-free adhesive mixture and ensures accurate dispensing without voids or gaps.

One-Click Cleaning Function: We recognize that efficient cleaning of equipment is as important as the potting process itself. To that end, our dispensing equipment includes a one-click cleaning function. This function enables an effortless and swift cleaning of the hose and mixing tube. With a single click, any remaining adhesive within the system is removed, reducing waste and ensuring that your equipment is ready for the next use.

Our glue dispensing equipment is designed with the user in mind, streamlining the potting process to increase efficiency and maintain the quality of your electronic assemblies. It is an indispensable tool in achieving the most precise and reliable potting results.

Conclusion

In summary, the journey towards achieving an optimal electronic potting process may appear complex, but with the right understanding, appropriate materials, and cutting-edge equipment, the end result can be a seamless, highly efficient procedure that produces durable and reliable electronic assemblies. The investment in knowledge, quality materials, and advanced machinery will no doubt yield returns in the form of enhanced product performance and longevity.

FAQs

Q1: What is the role of potting in electronics?

A1: Potting in electronics is a process that involves encasing electronic components in a protective compound to shield them from environmental factors such as moisture, dust, heat, and mechanical stress. It also helps in enhancing electronic insulation.

Q2: What are the major types of potting compounds and their key characteristics?

A2: The major types of potting compounds are epoxy, urethane, and silicone. Epoxy compounds are known for their excellent adhesion, high rigidity, and resistance to extreme conditions, making them suitable for outdoor applications. Urethane compounds are appreciated for their flexibility, elongation, and abrasion resistance, allowing them to protect various substrates effectively. Silicone compounds offer wide operating temperature ranges and exert the least stress on components, although they are usually more expensive.

Q3: What are some important factors to consider when selecting a potting compound?

A3: Key factors to consider include the hardness of the compound for resistance and protection, the viscosity for application purposes, the color for aesthetics and LED visibility, and the thermal conductivity for managing heat produced by electronic devices.

Q4: How can an automatic dispensing machine improve the potting process?

A4: An automatic dispensing machine can significantly enhance the efficiency and accuracy of the potting process. Features like preheating function, adjustable resin-to-hardener ratio, dynamic mixing, glue tank vacuum, and one-click cleaning help streamline operations, optimize the potting process, and ensure high-quality outcomes.

Q5: What is the benefit of using a dynamic mixing nozzle in the potting process?

A5: A dynamic mixing nozzle ensures the homogenous mixing of the resin and hardener, which is crucial for the end quality of the potting process. The longer the nozzle, the better the mix, and always mixing under pressure can also improve the quality of the resulting compound.